Body panel insulation is a key collision repair component, enhancing structural integrity and vehicle performance by sealing gaps against air, moisture, and thermal fluctuations. It improves energy efficiency, reduces noise levels, and increases durability through rigid foams, flexible sealants, and adhesive tapes. Proper installation techniques and regular quality checks ensure high-quality, safe, and satisfied repairs.

In the realm of collision repair, efficient and effective body panel insulation is a game-changer. This article delves into the fundamentals of body panel insulation, elucidating its pivotal role in enhancing repair quality and reducing energy consumption. From understanding the basic principles to exploring the multifaceted benefits, we guide you through best practices for installation. Discover how this innovative technique revolutionizes shop operations and ensures superior results.

- Understanding Body Panel Insulation Basics

- The Role of Insulation in Collision Repair

- Benefits and Best Practices for Installation

Understanding Body Panel Insulation Basics

Body panel insulation is a critical aspect of collision repair, playing a significant role in both the structural integrity and overall performance of a vehicle. At its core, it involves the process of filling and sealing gaps within car bodywork to prevent air and moisture intrusion. This not only enhances energy efficiency but also prevents corrosion, ensuring that a vehicle retains its structural strength and aesthetic appeal over time.

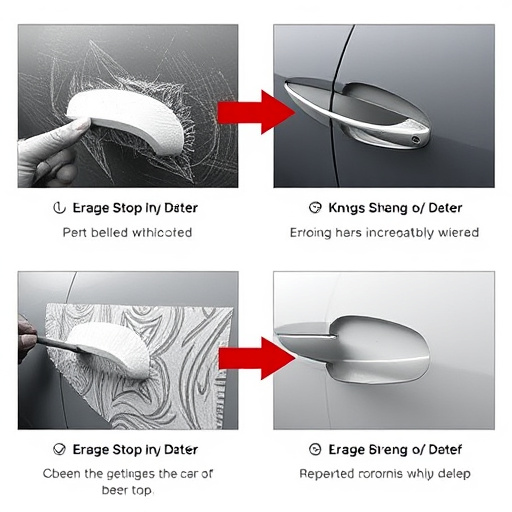

The key benefits of proper body panel insulation include improved thermal management, reduced noise levels inside the cabin, and enhanced durability. In collision repair shops, skilled technicians employ specialized materials to achieve this, such as rigid foams, flexible sealants, and advanced adhesive tapes. By integrating these solutions seamlessly into car body repair processes, workshops can ensure that every repaired vehicle meets high standards of quality, safety, and comfort for its occupants—an essential consideration in today’s market where customer satisfaction and environmental sustainability are paramount.

The Role of Insulation in Collision Repair

In collision repair, body panel insulation plays a pivotal role in ensuring the quality and longevity of car paint services. Beyond simply protecting the panels during the repair process, insulation acts as a critical barrier against environmental factors that can compromise the integrity of vehicle repair services. By minimizing thermal fluctuations and preventing moisture intrusion, it safeguards the painted surface, maintaining its smoothness, color consistency, and durability.

This process is particularly essential in the intricate world of car repair services. Efficient body panel insulation not only speeds up the overall restoration process but also minimizes the risk of future damage. It helps to preserve the structural integrity of the vehicle, ensuring that every patch, fix, and repaint is long-lasting. Thus, for top-notch car repair services, prioritizing adequate body panel insulation is indispensable.

Benefits and Best Practices for Installation

Body panel insulation offers numerous benefits for collision repair shops, enhancing both the quality and efficiency of auto body repair processes. Firstly, it helps in maintaining the structural integrity of the vehicle by providing extra support during the restoration process. This is particularly crucial when dealing with complex car body restoration tasks where precision and stability are paramount. By insulating panels, technicians can ensure that the repaired sections remain rigid and true to their original dimensions, preventing warping or misalignment.

When it comes to best practices for installation, proper preparation of the panel surface is key. Cleanliness and de-greasing are essential steps to guarantee optimal adhesion of the insulation material. Using specialized tools and techniques ensures a seamless fit, minimizing gaps or overlaps. Trained technicians should follow specific application guidelines to achieve the desired level of thermal and acoustic protection without compromising structural integrity. Regular quality checks during installation further ensure that the final results meet industry standards for automotive collision repair.

Body panel insulation has become an indispensable tool in modern collision repair shops. By understanding its basics, recognizing its crucial role in enhancing repair quality and efficiency, and adhering to best practices during installation, technicians can ensure superior results and contribute to the overall sustainability of automotive craftsmanship. Incorporating body panel insulation into standard procedures not only improves vehicle performance but also promotes energy efficiency, making it a game-changer in today’s eco-conscious auto industry.